For service we need your injector set and contact information sent in. It's easy!

We do it like this...

First things first:

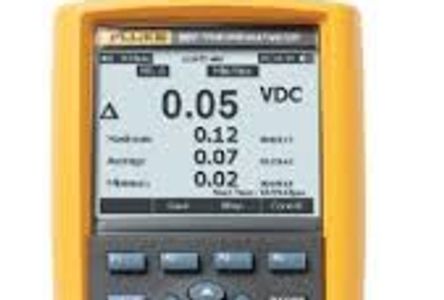

The very first step is electrically testing an injector. There are several ways injectors "foul out", and most of those are corrected through our specialized process. However, an electrically failed injector is a truly failed, and unrepairable, injector. A series of electrical testing is performed as a start to determine the overall integrity of the injector. Most pass, then it's on to the next step!

Current state-of-performance analysis:

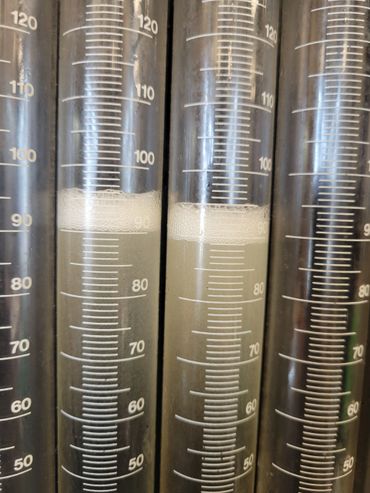

Now that the injector has passed electrical testing, we need to see what it's been doing in the engine. Rigged to a mock fuel rail, with synthetic fuel supply, the injectors run simultaneously on a state-of-the-art testing machine by ASNU. Flow-rate and balance are measured, spray patterns analyzed and in depth leak testing performed. All initial findings logged on a test report. Now we know what the engine has been trying to work with. This is great diagnostic information and a baseline of what we're up against.

Now the fun part:

The injectors are stripped of their components, including internal micro-filter. They go through highly specialized ultrasonic cleaning, not duplicated with other equipment. The injectors will pulse electrically, and with varying frequency, while in the ultrasonic tank, which causes a backflush effect. Contaminants are broken up, dissolved, and purged from the injector. This is the slow part! Cleaning is critical and can not be rushed. Once injectors are internally cleaned, and that's the key is internally cleaned, we go back to the test side of things.

And we're back:

Now that the injector has passed electrical testing and been properly cleaned, we again measure flow-rate and scrutinize spray patterns and leak-down levels. We will verify proper injector performance. Findings are, again, logged on the test report and comparisons made. All passing injectors are reassembled with new filters, seals, pintle caps and various other components as required. Test reports are provided with the completed injector set. The injectors are ready to install!

Gas Injector Cleaning Process

Check out this great video

Video

Check out this great video

.jpeg/:/rs=w:370,cg:true,m)

.jpeg/:/rs=w:370,cg:true,m)

.jpeg/:/rs=w:370,cg:true,m)

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.